Retirei esse texto da obra "Submarine Warfare" de Antony Preston, onde ele fala dos tipos de AIP e elogia longamente o sistema Stirling dos suecos. Apesar de a obra ser de 1998, já comenta que a Siemens estava buscando o uso de células de combustível que utilizem o metanol para a extração de hidrogênio:

THE AIP SYSTEM

During World War II the Kriegsmarine had experimented

with a closed-cycle diesel system as an alternative

to the Walter perhydrol-fuelled turbine.

Postwar, the Americans and British experimented

with high-test peroxide, but the Soviet Navy was

more impressed with the Kreislauf system, and

designed the Project 615 'Quebec' class coastal

submarines around the concept. What the Soviets

called a 'single propulsion system' ran submerged on

an internal supply of liquid oxygen (LOX). The

oxygen was added after the exhaust gases were

filtered through a lime-based chemical absorbent. The

boat could also run its Kreislauf diesel in the normal

way, using a schnorkel.

The 'Quebec' had three engines, a 32D 900bhp

diesel on the centre shaft and two M-50P 700bhp

diesels on the outer shafts. In addition a lOOhp 'creep'

motor was coupled to the centre shaft and a back-up

diesel-generator aft. The boat could be run at slow

speed using the centreline diesel only. Soviet records

suggest that experiments had started before 1941,

probably with the small coastal boat M.92, and other

closed-cycle designs were prepared after the

'Quebec'. Because LOX cannot be stored for any

great length of time these 467-tonne (460-ton) boats

could not operate far from a base. It was also a

dangerous system; at least seven suffered explosions,

and one of these, M.256, sank after being flooded

during firefighting efforts. One boat with the Walter

turbine AIP system was built, the 965-tonne (950-ton)

Project 617 S.99, known to NATO as the 'Whale'

type. The 5.99 made 315 dives using her Walter

system, in 1956-9, but in May 1959 she was badly

damaged by an explosion, and was never repaired.

After these boats were decommissioned in the early

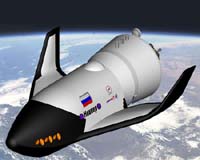

1960s interest in AIP lapsed, but recently the Russian

Rubin Bureau announced that it can offer an AIP

system for the new 'Amur' type SSK. Information

released shows that it is a fuel-cell system (see

below).

The most successful AIP system so far is the

Stirling engine. Developed from a patent dating back

to 1816, the Stirling cycle burns diesel fuel in pure

oxygen, in a pressure vessel. The Swedish submarine

builders Kockums AB of Malmö own the rights to the

Stirling engine, and tested its V4-275R 75kW engine

in the serving submarine Nacken. This proved

successful, with less vibration than a conventional

diesel-generator, and considerably lower noise levels.

In fact it is possible to conduct a conversation while

standing alongside a running Stirling engine. Since

then the A 19 type 'Gotland' class have been built

from the outset with Stirling engines, and the system

has been evaluated by a number of navies. Despite

rumours of submarines running entirely on four

Stirling engines, Kockums denies this, pointing out

that the amount of LOX required would be impossible

to fit into the submarine's hull.

The German Navy followed a different route,

funding Siemens and HDW in the development of a

Proton Exchange Membrane (PEM) fuel cell capable

of generating 40kW. As with the Stirling principle, the

idea is an old one, dating back to 1839. In essence a

fuel-cell reverses the process of electrolysis, using a

chemical reaction to combine hydrogen and oxygen,

thereby producing electrical energy, heat and water.

The heart of the PEM system is a solid polymer

electrolyte in the form of an ion exchange membrane

in contract with a platinum catalyst and carbon paper

electrodes. The membrane is positioned between the

fluid flow field and the cooling units in such a manner

that hydrogen ions pass through it and combine with

hydrogen anions. As long as hydrogen and oxygen are

supplied the fuel cell will continue to produce power.

A single fuel cell cannot produce more than 1.48V

and therefore several must be stacked to form a

module. The main drawback to the system is the cost

of materials, and HD W has so far not offered it for

export. The Federal German Navy tested a lOOkW

prototype installation in the old Type 205 boat U.I,

and the Type 212 boats currently under construction

will have a 400kW version.

OTHER AIP SYSTEMS

After the fuel cell trials the U.I was made available by

the Navy to TNSW for trials of a closed-cycle diesel

AIP system (CCD). This has the advantage of being

simple, the most complex part being the waterabsorption

system developed by Cosworth

Engineering. The engine exhaust gas is 'scrubbed'

with water to remove the carbon dioxide, and in the

same process the water vapour is condensed. Surplus

carbon dioxide is eliminated by adding a small

quantity of argon gas. The great virtue of the CCD

Left: HMS Ursula, the third of the 'Upholder' class. In

Canadian service she will be armed with the US Navy's

Mk 48 Model 4 torpedo and a Canadian towed sonar array.

system is its use of the same diesel for schnorkelling

or as an AIP unit, a great saving in cost. The system is

being marketed by TNSW and RDM (as the Spectre

system). The TNSW trials with U.I had the rare

benefit of comparing like with like: both the fuel cell

and the CCD being tested in the same hull.

The only other AIP system available is the French

(Module d'Energie Sous-Marin Autonome [MESMA])

system, which uses an oxygen-ethanol fuelled steam

turbine. Conceived in the early 1980s by the Bertin

company, it was taken up by DCN, the French Navy's

design and procurement bureau, in collaboration with

Empresa National Bazan in Spain. Although the

French Navy has not installed MESMA in a submarine,

it has been sold to Pakistan for fitting to new

Agosta-90B type SSKs.

The excitement over AIP has led to exaggerated

claims about its potential. Some commentators claim

that the advent of AIP has created a third category of

submarine, the SSK+AIP, but the fact remains that

only one navy has a modern AIP system operating.

Three more will have systems in service after the turn

of the century (counting Italy's acquisition of the Type

212 design), but a number of experienced operators

are still not sufficiently convinced to commit

themselves.

FUTURE DEVELOPMENTS

AIP enthusiasts point to potential developments. The

CCD system has great promise, with such improvements

as electronic fuel-injection and electronically

actuated valves. These improvements will allow the

operator to select engine-characteristics from a menu

of choices. The Solid Oxide Fuel Cell (SOFC) would

use natural gas as fuel, resulting in a single propulsion

system for surface and submerged propulsion.

Siemens is also known to be working on a fuel cell

using methanol as the base fuel to generate hydrogen.